- SMED was created at Toyota, where Shigeo Shingo, who also invented the Poka-Yoke concept, set out to minimize press setup times to under 10 minutes.

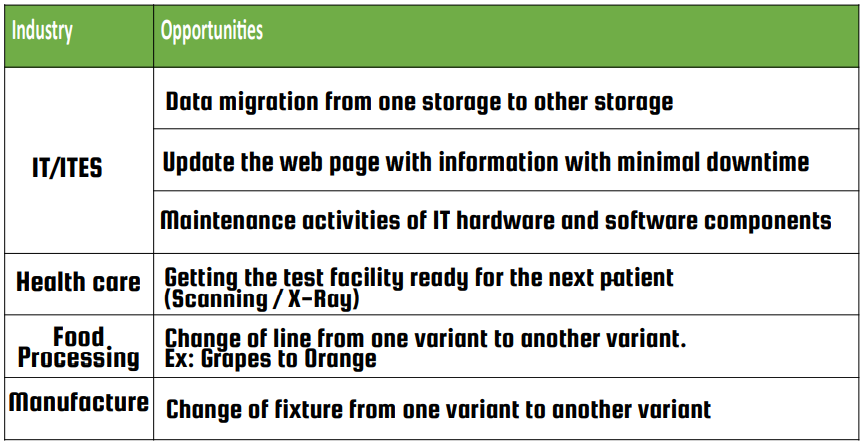

- SMED (single minute exchange of die) is a waste-reduction technique used when switching from one product manufacturing (service offering) to another product manufacturing (service offering)

- Rapid changeover is vital for reducing production lot sizes and, as a result, improving flow by reducing production loss and variability.

- The term "single minute" does not imply that all changeovers and startup times should take only one minute but should be under 10 minutes (in other words, "single-digit minute")

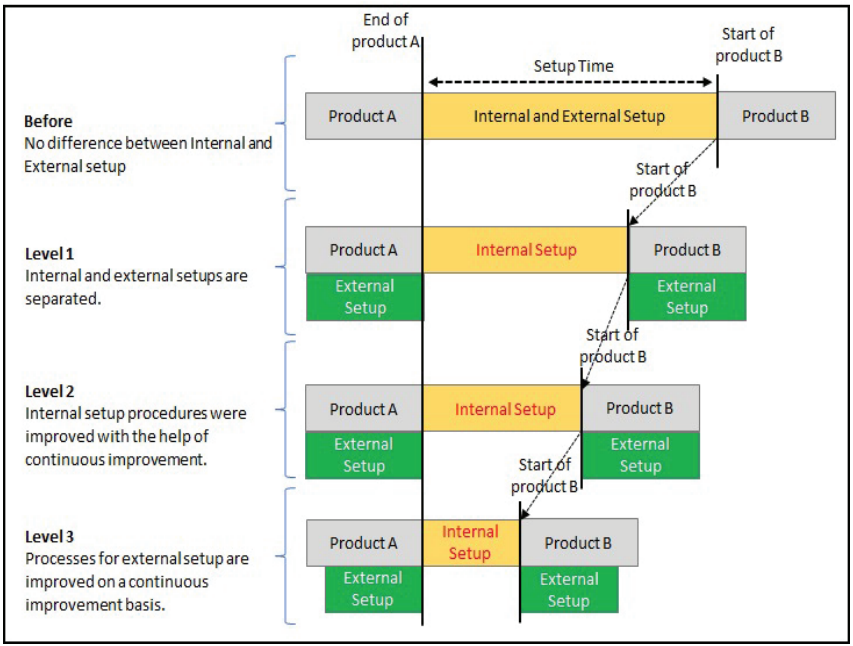

- When it comes to reducing setup times with SMED methodology, it's necessary to distinguish between internal and external setup.

- Internal setup happens after the machine or process has been halted, resulting in a major reduction in productivity

- On the other hand, in the case of an External setup, everything continues to work as usual, with no interruptions in value creation

- Unlike traditional setup methods, which do not distinguish between internal and external setups, SMED places a strong emphasis on this distinction.