Six Sigma Frequently Asked Questions

Six Sigma & It's Applications

Lean manufacturing or Lean Production or Lean Management,often only "Lean," is a systematic method for waste elimination or minimization with an intent to increase process efficiency and performance gain.

Waste is that for which the customer is not willing to pay.

When waste is reduced, there is a significant reduction of non-value-added activities leading to the process's fast-tracking. Thus, Lean is about process acceleration.

Six Sigma has many definitions; here is the most suitable one:

Six Sigma is a disciplined, data-driven approach and methodology to reduce variation in processes that enhance the system's performance, and directly or indirectly translates into customer satisfaction and significant financial gain.

Each term of the definition is essential – 'disciplined', 'data-driven', 'methodology', 'reduce variation', and 'customer satisfaction'. The most important is a significant financial gain. Unless Six Sigma translates into financial gain, organizations would have no interest in deploying it.

Six Sigma is a metric system. Sigma levels 1 to 6 define the robustness of the process in ascending order. Higher the Sigma value, the better the ability of the process to deliver superior, consistent output.

| Sigma Level | Defects Per Million Opportunities |

|---|---|

| 1 | 6,90,462 |

| 2 | 3,08,000 |

| 3 | 66,807 |

| 4 | 6,210 |

| 5 | 233 |

| 6 | 3.4 |

As the Sigma value increases, the defects per million opportunities reduce significantly.

Six Sigma is a Methodology

It includes

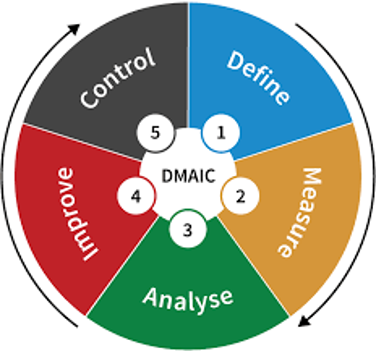

- A clearly defined and structured approach for solving complex problems

- DMAIC or DMADV methodologies, proven to deliver results

Six Sigma is a Journey

While other Quality initiatives focus on detecting and correcting defects, Six Sigma focuses on creating robust processes so that the cause of the errors is either eliminated or reduced. Six Sigma is best when applied over a longer duration. It is a journey to achieve the desired perfection levels.

By reducing variation in the process, the process would increase accuracy; hence, Six Sigma is all about Process Accuracy.

Lean + Six Sigma = Lean Six Sigma

Lean Six Sigma uses the concepts of both Lean & Six Sigma to drive significant business results. Most projects can be executed with Six Sigma DMAIC or DMADV methodology. It is useful to apply Lean concepts on a need basis. For instance, using the Value Stream Mapping in the Analyze phase for time reduction, and Kanban or Production Levelling or Standardization of Lean in the Improve phase to find a solution.

Lean + Six Sigma = Lean Six Sigma

Lean is all about eliminating/reducing waste in the process

Six Sigma, coupled with Lean knowledge, is a great value addition. Lean concepts complement Six Sigma in many ways. Using Lean makes process-based analysis much faster and easier in complex Six Sigma projects. Lean also helps to find solutions in the Improve phase of Six Sigma.

Lean6SigmaPro recommends learning Lean and Six Sigma independently and combining the methodologies as required in projects.

Unfortunately, most training institutes incorporate a few Lean elements in some Six Sigma phases and label the course as 'Lean Six Sigma.' Lean6SigmaPro firmly disregards such means as a disrespect for the Lean concept.

Six Sigma has many applications. It is traditionally used to achieve Process and Operational Excellence. However, it is increasingly being used as a revenue-generating tool in Revenue Acceleration projects.

Process and Operational Excellence, as the name suggests, is about achieving excellence in Operations. It focuses on parameters like quality, cost, deliveries, and customer and employee satisfaction. Effectively used, Six Sigma can

- Enhance the quality standards of an organization

- Increase profits by increasing sales, reducing expenses, and being more competitive in the market

- Strengthen the delivery adherence

- Improve customer, stakeholder, and employee satisfaction levels

Some sales-related projects that can benefit from Lean Six Sigma are Maximizing Revenue, Faster Revenue Recognition by Increase in Repeat Orders, Cross-Selling, Better Forecasting, and Trend Analysis.

Read Lean6SigmaPro founder's blog Is Six Sigma Still Relevant to learn more about the application of Lean Six Sigma/Six Sigma.

Six Sigma can be of great help in the service industry while improving service quality and service delivery. It can reduce service costs and increase the quantum of sales and customer satisfaction scores. It can aid faster revenue recognition and revenue generation.

The Lean6SigmaPro team has applied Six Sigma to various service industry projects, impacting millions of dollars. The following are some projects that stand to benefit from this methodology.

Process/Operational Excellence

- Increase in Productivity of Agents

- Increase in SLA Adherence

- A decrease in Quality Errors/mistakes

- Reduce Turnaround Time for Customer Calls/Queries

- Reduce Response and Resolution Times

- Increase Customer/Stakeholder/Employee Satisfaction

- Deliver Productivity for Customer

- Increase in Team's Agility

- Increase First Level Resolution

- Decrease Reopen Rates

Revenue-Driven Projects

- Increase in Sale of Service Offered

- Reduce Credit/Debit Rebills

- Faster Revenue Recognition

- Reducing the Time to be Billable

Other Projects

- Reduction of tickets/calls (proactive actions in fixed price model)

- Identifying the right set of qualities required for agents & recruiting the right professionals

The ultimate goal of these Lean Six Sigma projects is to increase business sales and outcome; and, most importantly, profit.

Note: A word of caution - none of these projects should cause loss of employment. If any of the projects lead to the loss of jobs, then alternative employment opportunities should be created. An option is to increase the volume of work to ensure employment for everyone.

In the Food Processing Industry, the perishable nature of food offers great opportunities to optimize food utilization. The Lean6SigmaPro team has worked with the food industry on a couple of assignments and reduced food processing wastage by 30–90%. The sector also offers various options to optimize the consumption of raw materials and optimize the supply chain. Some of the projects are:

- Reduce food processing wastage (by over 80%)

- Optimize the supply chain to deliver faster and fresher food

- Increase in productivity and resource utilization

- Increase in sales due to enhanced freshness

- Decrease in expenses due to waste product reduction

- Increase in usage of food products at the customer end

Lean6SigmaPro's experience of how the beverage and breweries industry works is through interaction with the participants in some public training batches. The Lean6SigmaPro team has trained almost a dozen professionals from the beverage/breweries industry.

There are four significant challenges in the industry. Here is a perspective on how they can be overcome:

- One of the critical concerns is the percentage of rejection wastage of raw material, semi-finished products, or at the end of the production. Lean6SigmaPro strongly recommends a Quality Improvement project to identify the causes of rejection. It could be raw material, process, or process parameter. Analysis of Variance (ANOVA)/Regression can be used to identify the root causes of variations. Simple Visual Management can also help in enhancing quality.

- The beverage/breweries industry often suffers from productivity issues. It generally has a higher turnaround time due to certain process constraints and a lack of synergy. Excessive changeover time from one variant to another is also a concern, as a smaller company cannot afford to have a dedicated line for each product. On the other hand, it is essential to supply fresh beverages to customers. Lean6SigmaPro highly recommends applying some Lean tools here. Tools like Value Stream Mapping, Single Minute of Exchange of Dies, Line Balancing, Kanban, and Spaghetti diagrams can help overcome a few challenges.

- Another challenge is maintaining a standard taste despite variation in the input. Lean6SigmaPro recommends the Design of Experiments to arrive at an optimal solution for maintaining a uniform taste. Specific process optimization is a must, given the constraints of raw material the industry faces.

- The sector suffers from either short supplies or excess quantities produced due to high demand fluctuation & shorter shelf life on the supply side. Kanban & Supermarket would be a great help here. This can also help the company retain its market share and capture new markets when the demand arises. Trend Analysis & Forecasting could be a good idea, as well. However, it should be employed after strengthening the process to a certain level.

All of Six Sigma may not be useful in Sales & Marketing. However, tools like Probability, Hypothesis testing, Regressions, Trend Analysis, Forecasting, Design of Experiments can be a great advantage. These tools can help identify and prioritize customer segments where the organization can drive higher sales.

The Lean6SigmaPro team has helped one of their clients from the Technology industry to increase their sales by 1.75%, which translated into an increase of millions of dollars annually.

Yes, healthcare professionals can study both RPA and Six Sigma. It is recommended to decide between the two based on the learner's key strengths; Six Sigma requires a certain amount of mathematical knowledge, at least beyond the Green Belt level. RPA requires some coding expertise. The learner's domain expertise, coupled with Lean Six Sigma or RPA, would be a great asset to the healthcare industry.

Absolutely!!

Startups need to start focusing on profitability within the first year. Lean6SigmaPro recommends reading the blog,

"Is Six Sigma still Relevant?" to learn more about how Six Sigma can benefit startups.

It is vital first to understand what Six Sigma is. There are many definitions of Six Sigma, but this one is the most relevant.

Six Sigma is a disciplined, data-driven approach and methodology to reduce variation in processes that enhance the system's performance, and directly or indirectly translates into customer satisfaction and significant financial gain.

Now, how many industries in India keep process variation within acceptable limits? Most industries like Manufacturing, Automotive, Automobile, Food Processing, Healthcare, IT, ITES, and Supply Chains meet the defined limits only 80–90% of the time. Vast amounts of money are wasted due to inefficient processes. If process variations are reduced, substantially lower rejection rates are achieved, and millions of dollars are saved. Good Six Sigma personnel can add a couple of million dollars annually to their company's coffers. That is why they are an asset to the industry.

Please note, studying Six Sigma does not merely mean getting a certificate. It means applying the knowledge. Remember the quote Knowledge is not power; applied knowledge is power; this applies to Six Sigma.

Certification

The roles and responsibilities of various belts differ from organization to organization. But on a broader level, we define them as below.

Yellow Belt (YB)

A Six Sigma Yellow Belt is a team member who assists Green Belts in a Six Sigma project. A Yellow Belt undergoes formal training in Six Sigma concepts. In most organizations, either Black Belts or Green Belts train their Yellow Belts during the project execution. Formal training for all the yellow belts adds to the success of the project.

Green Belt (GB)

A Six Sigma Green Belt is an individual who leads a Six Sigma project. He/she is usually part of the process in which the project is being driven and knows the process very well. A Green Belt needs to undergo more intense training in Six Sigma than a Yellow Belt. The training includes the use of statistical tools. Green Belts learn to make inferences from statistical analyses, with or without the help of Black Belts. Green Belts carry a higher responsibility of delivering Six Sigma projects and are required to dedicate ~20-25% of their time in executing them.

Deliverables of a Green Belt:

- Lead Projects & Execution

- Team and Project Structuring

- Six Sigma Project Results

- Share Best Practices

Black Belt (BB)

A Six Sigma Black Belt is a full-time change agent and improvement leader who guides the Green Belt in executing projects. He trains and supports Green Belts and budding Black Belts in project execution and statistical analysis. Black Belts also lead more complex Six Sigma projects. Unlike the Green Belt, an expert in the process, the Black Belt need not be a process expert. Instead, he/she is a Six Sigma expert with sound business acumen. The Black Belt is a crucial member of the entire Six Sigma value chain for most organizations in India and abroad. He influences decision making at various levels, such as choosing appropriate Six Sigma projects or selecting the right Analysis tool. He contributes a significant amount of time to Six Sigma projects. An experienced Black Belt is also an advisor to executives and business unit managers.

Deliverables of a Black Belt:

- Six sigma strategy and roll-out plan for the given process/area

- Lead & execute projects

- Help and guide Project Resources/ Help remove project level barriers

- Team and project structuring

- Six Sigma Project Results

- Train and mentor Green Belts and less experienced Black Belts

- Share best practices

Master Black Belt (MBB)

Master Black Belts are methodology and statistical experts. Their typical role in an organization is to support Black Belts in Six Sigma methodologies. They are responsible for the strategic deployment of Six Sigma and drive improvements in all business functions. They play a vital role in organizations that embrace Lean Six Sigma culture. They are, therefore, essential members of Lean Six Sigma implementation across all business functions. Smaller companies outsource this activity to an external consulting agency. Master Black Belts, together with Tenured Black Belts, are advisors to executives or the CEO. A Master Black Belt typically devotes 80% of his time to leadership and 20% to technical roles.

Deliverables of a Master Black Belt:

- Six Sigma strategy and roll-out plan in the organization/function

- Manage the project of the function

- Mentor teams

- Achieve Lean Six Sigma results

- Cross-Functional leadership

- Project execution

- Removing roadblocks

Six Sigma Green Belts (GBs) are like engines of Six Sigma projects. Black Belts support the business teams' efforts to identify and implement change. GBs are part-time Six Sigma Project Leaders. They are responsible for scoping projects, leading the project team, calling for help when needed, managing interfaces with business leaders, and ensuring sustainable results.

The goal of GBs is to apply the value of Six Sigma to the specific work environment and problems. They challenge the status quo where appropriate and seek and share ideas across boundaries.

Yes. If graduates have Mathematics or Statistics as one of their subjects and have a fair understanding of the process, they can start with Lean Six Sigma Green Belt. Alternatively, they can start with a Yellow Belt Certification.

If the professional has over two years of experience in Quality or Process, OR if the graduate has Statistics or Mathematics as one subject, they can start with the Green Belt directly. Alternatively, Lean6SigmaPro recommends starting with the Yellow Belt.

How to learn: Six Sigma is best understood by practice rather than theory. The initial classroom sessions are needed to understand the concepts, get a first-hand understanding of methodology and tools, and get exposure to Minitab or other statistical software. At the end of the classroom session, take up a training that lasts 4 to 6 days. Less than four days is inadequate, and more than six is unnecessary. It is also a recommendation from Lean6SigmaPro not to spend too much money on training. Opt for certification from recognized agencies like Exemplar Global, TUV SUD, KPMG, ISI, or IASSC. Avoid certification by local institutes as they lack credibility in the market.

Different levels of certifications: The accreditation level depends on what is expected from this training. Being a team leader, if there is no extensive application of Six Sigma concepts, the Green Belt certification is the right choice. If Six Sigma concepts are to be used extensively, then Lean6SigmaPro recommends the Black Belt certification. Furthermore, if the professional aspires to be a Six Sigma professional, Black Belt training is mandatory. Please read Levels of Six Sigma Certifications – YB, GB, BB, and MBB to understand each level's roles

The certification differs across various certifying bodies, but the general pattern is as follows. Please note that this is generic information.

Yellow Belt & Green Belt:: Attend stipulated training and pass the certification exam.

Black Belt:: Attend stipulated training, pass the certification exam, and complete a Six Sigma Black Belt project.

Note: Participants are requested to read certification guidelines from respective certifying agencies.

Follow the link below, which explains the benefits of Six Sigma in a simple manner:

Lean6Sigmapro on LinkedIn: "#5 Benefits of lean six sigma certification..."

It is undoubtedly worth it. Just be warned that mere certification has no value. If certified by a recognized agency and there is a practical use of the knowledge, then the sky is the limit. Good Six Sigma Black Belts are in great demand in India and will continue to be so for three or four decades. There is no replacement for Six Sigma.

Remember, Six Sigma is a problem-solving methodology, and we have innumerable problems in India. Not all of them require Six Sigma. However, if nothing works, with Six Sigma, there is hope.

Good Six Sigma Black Belts are highly paid professionals. In most companies, they figure in the top ~5% pay bracket.

Lean6SigmaPro founder recommends reading the Blog “Is Six Sigma Still Relevant?” to learn more about the future of Six Sigma across industries.

Write to Lean6SigmaPro at info@xergy.co.in for any further questions.

It depends on various factors. However, Lean6SigmaPro suggests getting the certificate from an internationally recognized body like Exemplar Global, TUV SUD, IASSC, ASQ, KPMG, or ISI, which are well-known bodies and have credibility. Certification through local institutes is not recommended. Such institutes lack credibility in the global market. The interviewer or employer may be unaware of the institute, even if it is located within the city. Finalizing an institute is a one-time process, so Lean6Sigmapro strongly recommends opting for a globally-known agency. It is also recommended to get the experience of driving projects.

The process is simple. Get trained, appear for the exam, and complete one or two projects. (The project requirement varies from institute to institute.) The course cost also depends on the institute. Green Belt costs typically range from INR 14,000 to 28,000. Black Belt costs range from INR 35,000 to 70,000/- Course costs include examination and certification. Local training institutes that issue their certificates charge less. However, the certificate does not bear much value.

Both Lean & Six Sigma evolved through the industry. Thanks to organizations like TUV SUD, there is a structure for the training and certification process. Globally-known certifying bodies like the Exemplar Global, TUV SUD, ASQ, IASSC, KPMG, and ISI are good. Lean6SigmaPro has named these organizations because they have an accepted certifying procedure and credibility in the market.

It is important to note that in Six Sigma, applied knowledge is more important than a certificate. The certificate matters, but it is crucial to know how to make use of the learning. Hands-on experience of driving Six Sigma projects is needed during training.

If one is looking to learn Lean Six Sigma at an optimal cost, enroll with Lean6SigmaPro's Green Belt training & certification program. This program does not require any prior knowledge of Lean Six Sigma. Lean6Sigmapro starts with the basics. Lean6Sigmapro innovative, simulation-enabled, and gamified curriculum helps the professional learn and master the concepts better. Lean6Sigmapro expert trainers answer queries and ensure there is complete clarity on the subject. India has multiple openings for Lean Six Sigma professionals. Lean6Sigmapro will help in becoming one.

It depends on various factors. Most professionals enroll for Six Sigma training after a few years in the industry. The pay scale, in this case, depends on their previous salary. Generally, post-certification salaries are better than the previous ones. However, it depends on their contribution to the company and the value addition that they bring.

In case of being a fresh graduate with Lean Six Sigma certification, the chances of getting a job are higher. Such a resume is preferred over others.

Green Belt

The certificate alone has little value. The certificate is a valuable asset if the professional has the knowledge to drive Lean Six Sigma projects. It has the power to increase compensation multifold.

License and knowledge together give the professional the following advantages.

For Business, Six Sigma is a great value addition for enhancing quality levels, increasing profits, helping deliver on time, increasing sales, and faster revenue recognition.

As a Professional, Six Sigma Green Belt certification can get enable a salary hike. The professional can achieve goals faster once the Six Sigma concepts are practiced at the workplace, thus becoming an asset to the organization.

A word of caution - salary depends on company regulations, performance, and other criteria. All organizations may not meet the expectations of the Six Sigma Green Belt certification or projects. The professional needs to evaluate what works best.

There is no prerequisite for Green Belt certification. However, it helps if the learner understands Process, Quality, and 7 QC. At Lean6SigmaPro, the basics are covered so that it is easy for participants to learn the Lean Six Sigma concepts.

The course and syllabus vary from company to company. However, the intention is to teach the learner the DMAIC methodology of Six Sigma and to provide Minitab practice. These are the tools needed to drive Lean Six Sigma projects.

It is okay to get Six Sigma certification without practical knowledge. However, it is meaningless if the learner does not make use of the learning after certification. It is a loss in terms of both money and career prospects.

It is recommended to do so after the Black Belt certification, not after the Green Belt certification. Being a certified Black Belt and having executed a couple of projects, the professional will have many opportunities outside the current work field.

It is difficult to say. Salaries depend on various factors like the company, the employee's role, and the nature of business. Green Belts generally earn more than those who are not Six Sigma certified. It depends on how well the professional applies the Six Sigma knowledge to real-life projects. Six Sigma certification is an asset, but it is valued only applied effectively.

It depends on where the certification is obtained. Many organizations incorporate a few elements of Lean in their Six Sigma training and label the course as Lean Six Sigma. This undermines the value of Lean. Lean, by itself, is a potent problem-solving tool. It is essential to learn Lean and Six Sigma separately to get the best of both.

At Lean6SigmaPro, both Lean and Six Sigma are valued and taught separately for Lean Six Sigma certifications. Lean6Sigmapro stands out in this respect.

Follow the link below to know more about the benefits of Six Sigma.

Lean6Sigmapro on LinkedIn: "#5 Benefits of lean six sigma certification..."

Yes. Six Sigma is an excellent leveler. Irrespective of the work experience, studying Six Sigma can be a game-changer for the professional's career. As per Lean6SigmaPro's experience, learners from various educational and professional backgrounds succeed in Six Sigma. It is recommended to train with the intent of driving large scale projects. A mere certificate is meaningless. Apply the knowledge and make a difference to the organization.

Yes, definitely. In fact, after ten years of experience in Quality, the learner must pursue the Six Sigma Black Belt certification. Green Belt is for junior roles. Black Belt training would help in many ways to accelerate the career as a Quality professional.

It depends. If the Green Belt training is used to solve complicated problems and drive high impact projects, the organization will value such a contributor. The certification can also help find a new job as the professional is better equipped than others in the field. However, this certification cannot be treated as the equivalent of a college degree.

Black Belt

It is assumed that the professional is eligible for the Lean Six Sigma training and certification. Different certification bodies have different criteria for eligibility. There are differences in the certification procedure of various organizations, but the process is simple.

TUV SUD:

- Attend Black Belt training.

- Complete the Six Sigma certification exam.

- Submit a Six Sigma project within eight months after completing the certification exam.

Based on the learner's final exam and project score, TUV SUD will award the Black Belt certification.

ASQ: Apply directly for an online exam, with an affidavit of completing a Six Sigma project. The learner will get the Black Belt certification on completing the exam.

IASSC: Apply directly for the exam. The learner gets the Black Belt on the successful completion of the certification exam.

Yes and No.

If the certification is only to upgrade the learner's resume, it may not have much value.

However, if the learner learns the tools and techniques well and uses them regularly in high impact projects, the Black Belt certificate can be a significant value-addition.

The answer is "It depends".

It depends entirely on the professional's career aspirations. The answer is "Yes" if Six Sigma is considered a career option or Six Sigma tools are essential in the current domain.

Do not study Six Sigma just for a certificate. That may not help much.

Remember the quote Knowledge is not power; applied knowledge is power. It is more important to make use of learning than to get a certificate.

Green Belt and Black Belt are different levels of Six Sigma certification. If Green Belt is considered as graduation, Black Belt would be post graduation. (Do note that this is an analogy. Six Sigma certification is not akin to graduation or post graduation).

Green Belts typically study the DMAIC methodology of Six Sigma. They learn to drive real-life projects. Black Belts handle the complex analysis and experiment design, which may be too challenging at the Green Belt level.

In terms of work, Green Belts usually participate in executing a Six Sigma project. They allocate 20–30% of their time to the project. Black Belts are responsible for driving or mentoring a Six Sigma project. They allocate 80-100% of their time to the project.

Lean6SigmaPro recommends reading Six Sigma Levels of Certification and their Deliverables

Lean6SigmaPro has the experience of training Six Sigma professionals for over 16 years. Furthermore, Lean6Sigmapro understands PMP well, so the answer is, it depends on the person who takes the exam.

A project manager with management experience might find PMP easier. Someone familiar with quality control, process excellence, and statistics would find Six Sigma more comfortable.

However, a person with no prior experience would most likely find the Six Sigma Black Belt much more difficult as compared to PMP, due to the statistical concepts involved. PMP is exhaustive. It takes time to understand. Nevertheless, Six Sigma is more complicated.

It depends on the project. But a good Lean Six Sigma Black Belt should deliver savings of $0.5+ mn/annum (tangible/intangible)

There are many career opportunities for Six Sigma Black Belts. The most popular ones are Six Sigma consultants or Process Excellence/Continuous Improvement Professionals. There are opportunities in the fields of Quality, Process, and Operations as well. There is no necessity to be in a Six Sigma role. The professional can have a great career irrespective of the domain.

If the professional is extremely good at driving high impact projects and saving the organization millions of dollars, then the sky's the limit

Irrespective of the certification body, work experience is a must before taking up the Black Belt training program and the exam. Without prior experience, it will be difficult to understand and relate to concepts like Hypothesis Testing Regression and Anova. The design of Experiments is even more challenging. The professional must have at least 4 Years of experience before taking up Black Belt certification.

Institute

Here are the criteria to choose an institute to learn Lean Six Sigma.

-

1. Trainer Experience:

Irrespective of the big brands, the experience of the trainer or faculty should matter. If the intention is to return to the workplace, use the learning and grow in the industry, then learn from someone who has done what is intended to be done. If the trainer does not have enough experience in driving projects, it will not help understand the concepts. Teaching theory might be successful, but sharing relevant examples relevant to the learner's industry would be a failure. Six Sigma is all about practical knowledge. The learner must learn the art of driving projects. Before enrolling for the training, find out how many projects the trainer has driven. Someone who has been training for a decade, without the experience of corporate consulting assignments, may have lost touch with the industry. That trainer may not be the best choice for an instructor. Ask for the instructors' LinkedIn profiles, go to their profile pages, and determine if they have done what the learner intends to do in the future. Select a trainer with over 100 projects experience to learn from.

At Lean6SigmaPro, each trainer has the experience of at least 150 projects. Lean6Sigmapro trainers are chosen to help learners with the right examples across various industries, from Manufacturing to Information Technology. - 2. Certifying Agency:

Get certified by someone with credibility in the international market, like Exemplar Global / TUV SUD / ASQ / IASSC / KPMG / ISI. - 3. Course Curriculum:

Ask for details of the course curriculum. Compare various institutes and choose the one which is the most exhaustive. Six Sigma is an exhaustive course. It is essential to choose wisely, as this learning is not intended to be repeated. A simple syllabus to help pass the exam and make one feel good is not useful. Mere certification does not add any value to the career. Focus on learning. - 4. Mode of learning & Minitab Practice:

As a learner, what is preferred: learning through theory lessons, or by simulations and hands-on practice, with real-life examples from the industry? Choose what works best. Hands-on Minitab practice is a must before the end of any training. If the learner has not operated the Minitab for a minimum of 6-8 hours in the class, it will be challenging to use it after the training is completed. - 5. The number of participants:

Individual attention is needed while training. The faculty must ensure that the learners get complete clarity in the subject. If the learners have questions about their industry, the trainer needs to answer them. Learners need attention and guidance when practicing p-values on the Minitab and draw inferences. Select an institute that limits the batch size to a maximum of 14 learners. It becomes challenging to accommodate more learners, especially for Minitab practice. - 6. Post Certification Support:

Six Sigma goes beyond theory. The learner's actual test starts when they start making use of the knowledge at the workplace. Check with the institute if the training and course material is good enough to drive real-life projects. Ask if the institute supports the learner on the field. If yes, ask how the support is provided? Is it just through a phone call or Skype? Or, can the learner schedule a time and meet them right in their city? -

7. Real-Life Project Experience:

Real-life project experience is critical. Especially if the learner is a Black Belt, they must have the ability to drive a Six Sigma project from scratch. A simulation project may help to analyze data and make a presentation. However, it is not enough at the Black Belt level. Executing a project is the ability to start a project from zero and take it to successful closure with good financial benefit to the organization. The learner can grasp concepts like Six Project Qualification, Project Selection, Balance Score Card, Threat Analysis, and Art of Managing the Change and the Stakeholder only when a project is executed in real-time. If the learner is a Green Belt, check if the institute allows participation in a project along with Black Belts.

At Lean6SigmaPro, real-life Black Belt-level Six Sigma projects are provided to the Black Belt trainees. A group of 4-6 Black Belt works independently on each project. They meet once a week, on a pre-defined day, to discuss and learn as a group. All groups are familiar with the working of other projects as well. This ensures a healthy exchange of information.

Certification Bodies

The way to judge a certification agency is its history, credibility in the market, and the certification process. Lean6SigmaPro values both IASSC and TUV SUD. However, given a choice, preference is given to TUV SUD. The organization has an immaculate track record, and its certifying procedure for Black Belt is more stringent than IASSC.

Affordability is another factor in favor of TUV SUD. One often mistakes a higher cost for more value. However, that is not true. TUV SUV certainly has an edge over its competitors in this respect.

Lean6SigmaPro Related

Payments can be made via Demand Draft / Cheque / Cash / Online transfer / other payment apps.

Click on the Enroll Now button to view the course page and make the payment.

For further details, please mail us at info@xergy.co.in or Call us on +91 968 698 7766

Yes, we will help you with a trial version of Minitab software.

Yes, we will train you on the Minitab software during the training program.

Yes, we provide real life projects to Black Belt certification programs.

*Live Projects are subject to the availability of projects and participants, the participants’ professional background, and specific case conditions.

Yes, we provide 100% free assistance in completing a real life project.

Yes, we offer placement assistance in the Lean Six Sigma field.