Measurement System Analysis (MSA)

-

MSA determines the amount of variation due the

measurement system. The objective method is to assess

the validity of a measurement system and minimize the

variation due to Measurement.

-

Measurement Systems Analysis (MSA) is a tool for

analyzing the variation present in each type of

inspection,measurement, and test equipment.

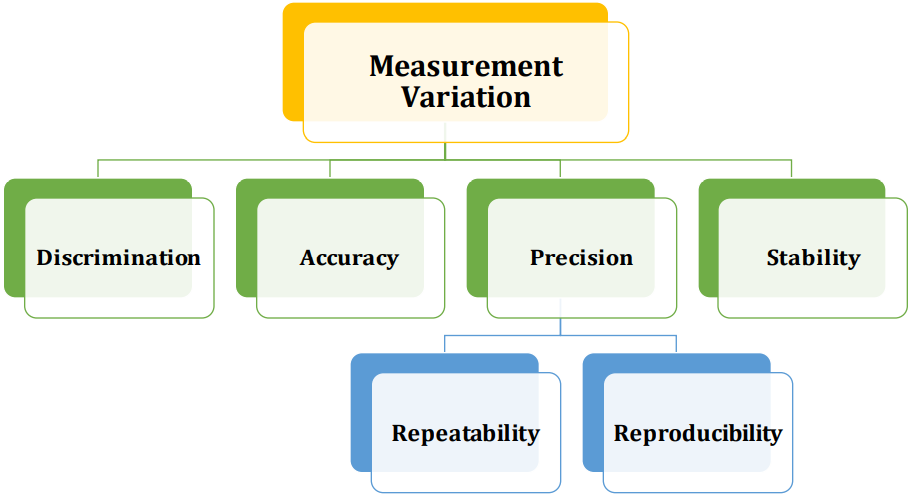

- MeasurementVariation can be classified as below

-

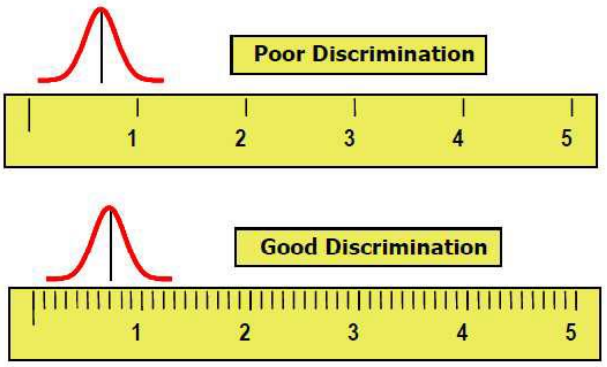

If the red distributions illustrate the process variation,

we would not be able to detect small (decimal) changes

to the process using the first measurementinstrument.

-

The second measurement device has better

discriminationthan the first.

-

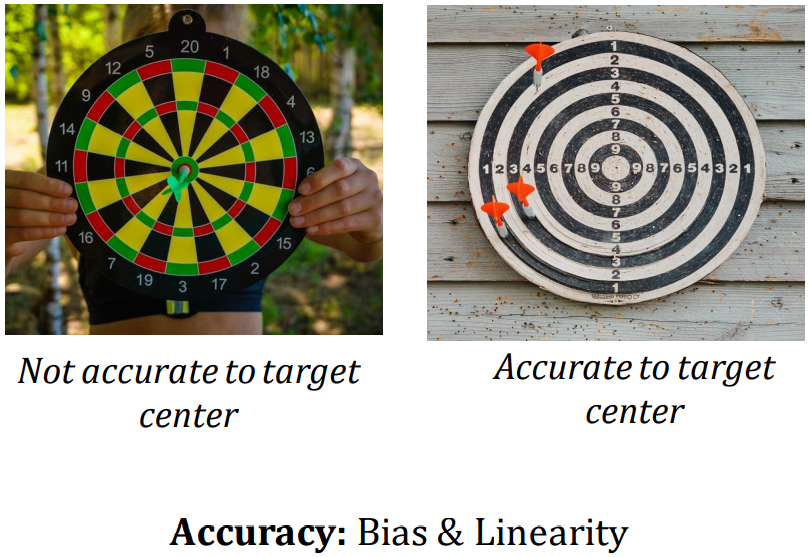

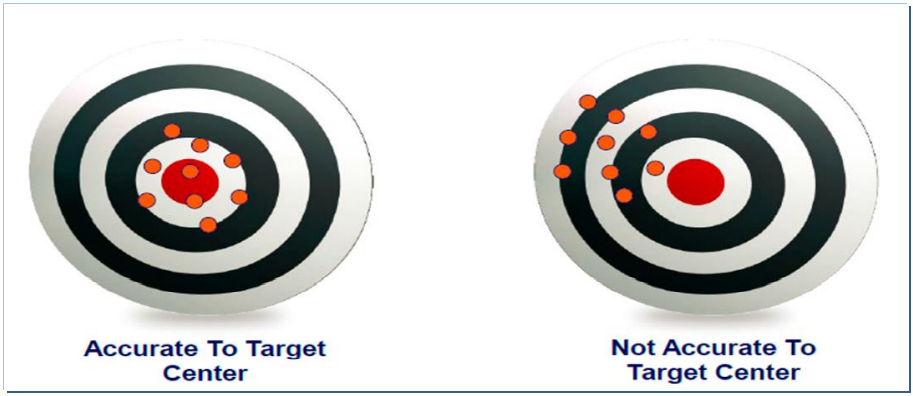

Accuracy is how close a value is to its true value. An

example is how close an arrow gets to the dartboard

center.

-

Accuracy is how close a value is to its true value. An

example is how close an arrow gets to the dartboard

center.

-

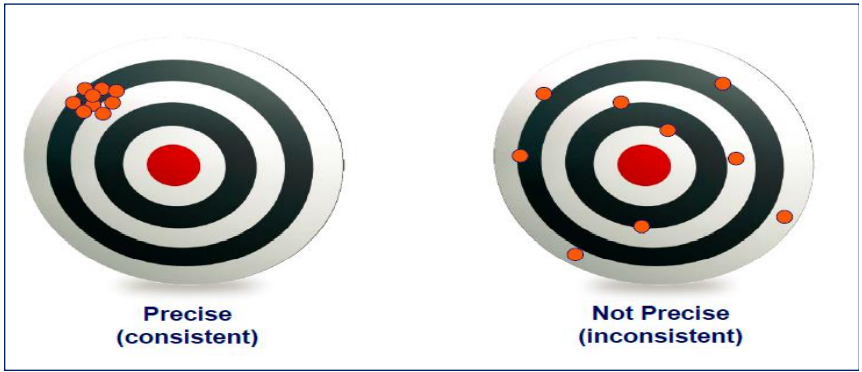

Precision is how repeatable a measurement is. An

example is how close a second arrow is to the first one

-

Precision describes the variation you see when you

measure the same part repeatedly with the same

device. It includes two types of variation Repeatability

& Reproducibility

-

The Measurement system must be both Accurate &

Precise

-

Repeatability: The variation due to Measurement

Gauge or poor gauge design. It is often the result of poor

design ofthe gauge or gauge system

-

Repeatability for Measurement System can be found out

by repeated measurement of the same unit with Same

Location, Same Measuring tools, Same Operator, Same

Parts.

-

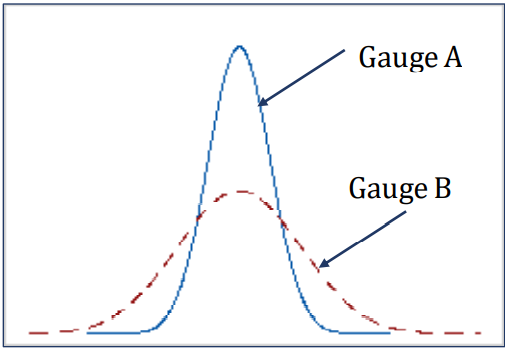

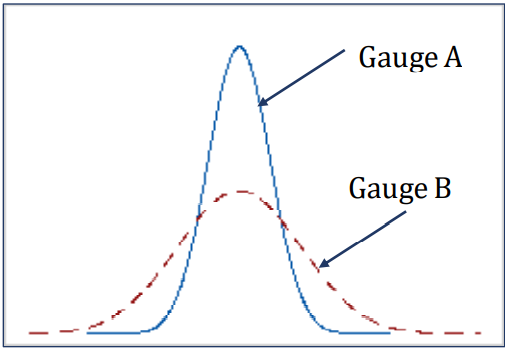

From the image below:

- Variation by Gauge A is lesser than B or

- Repeatability will be better with Gauge A

-

Reproducibility: The variation contributed due to

Appraisers (measuring people)

-

Reproducibility for Measurement System can be found out

by repeated measurement of different units with below

conditions*

-

Same Location, Same Measuring tools, Different Operators,

Different Parts

-

Note: *Conditions are industry-specific. Given conditions

are for Manufacturing & Service industry only, Non�Research oriented, Non-Pharma or Bio

-

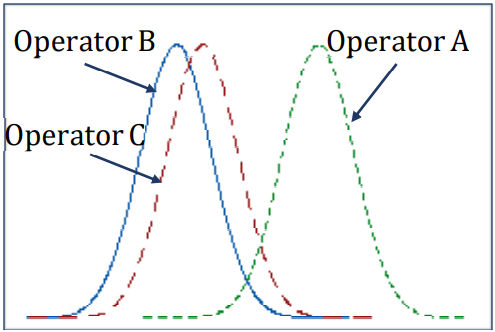

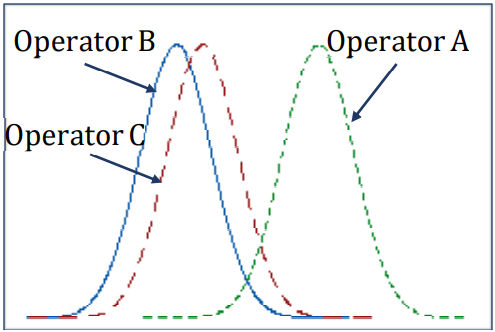

The variation in average

measurements between

Operator B and C is

much less than the

variation between

Operators A and C.

Therefore, the gage's

reproducibility is too

low.

-

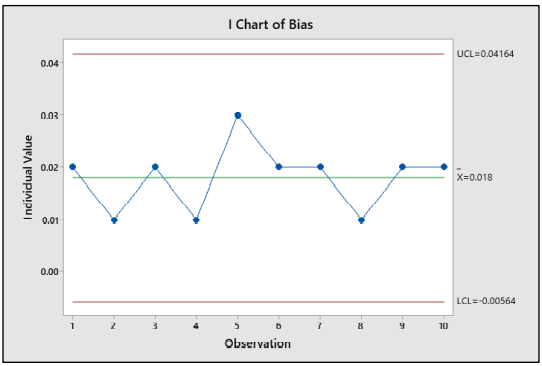

Measurement stability is the measurement system's

capacity to produce the same values over a given time

range while measuringthe same sample.

-

Master component or controlled component is

measured over time, and the Bias is calculated and

plotted against the time using control

charts. Measurement is stable, meaning the absence of a

special cause leaving only the common cause.

-

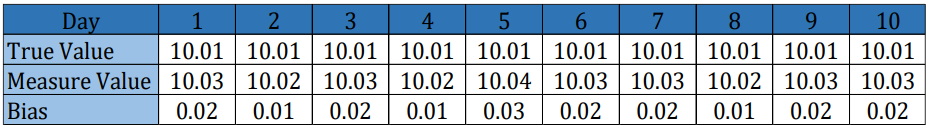

Let us consider the below data where Master gauge

measurementis taken for 10 days and Bias is calculated

-

Inference: As the Bias values are within the control limit

and no special cause noticed, we can conclude that Bias

in control and Measurementis Stable