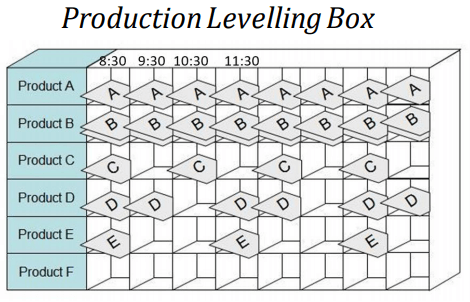

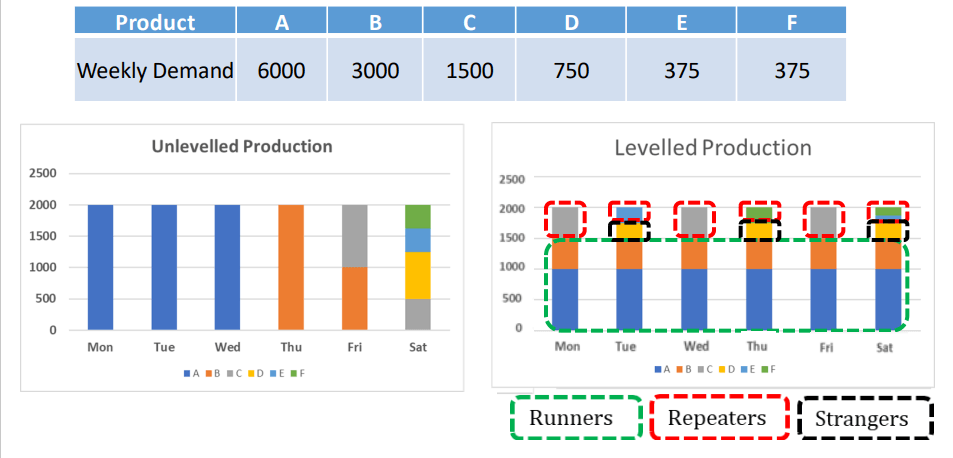

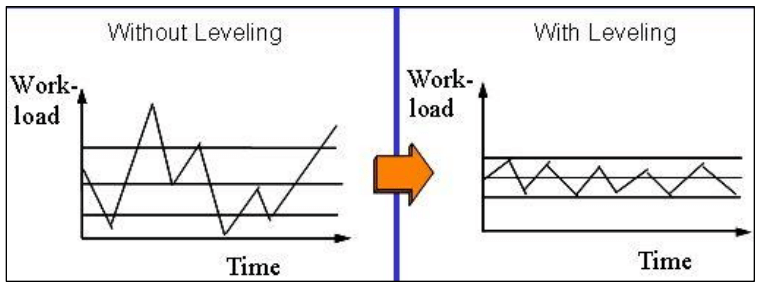

- Production levelling, also known as production smoothing, reduces Mura (unevenness) in production while also reducing Muda (waste).

- It's a part of the lean process improvement approach that helps companies balance unpredictable customer demand trends and remove manufacturing waste by leveling the type and quantity of production output over a set periodoftime