Blogs

The Evolution Growth And Significance of Lean & Six Sigma

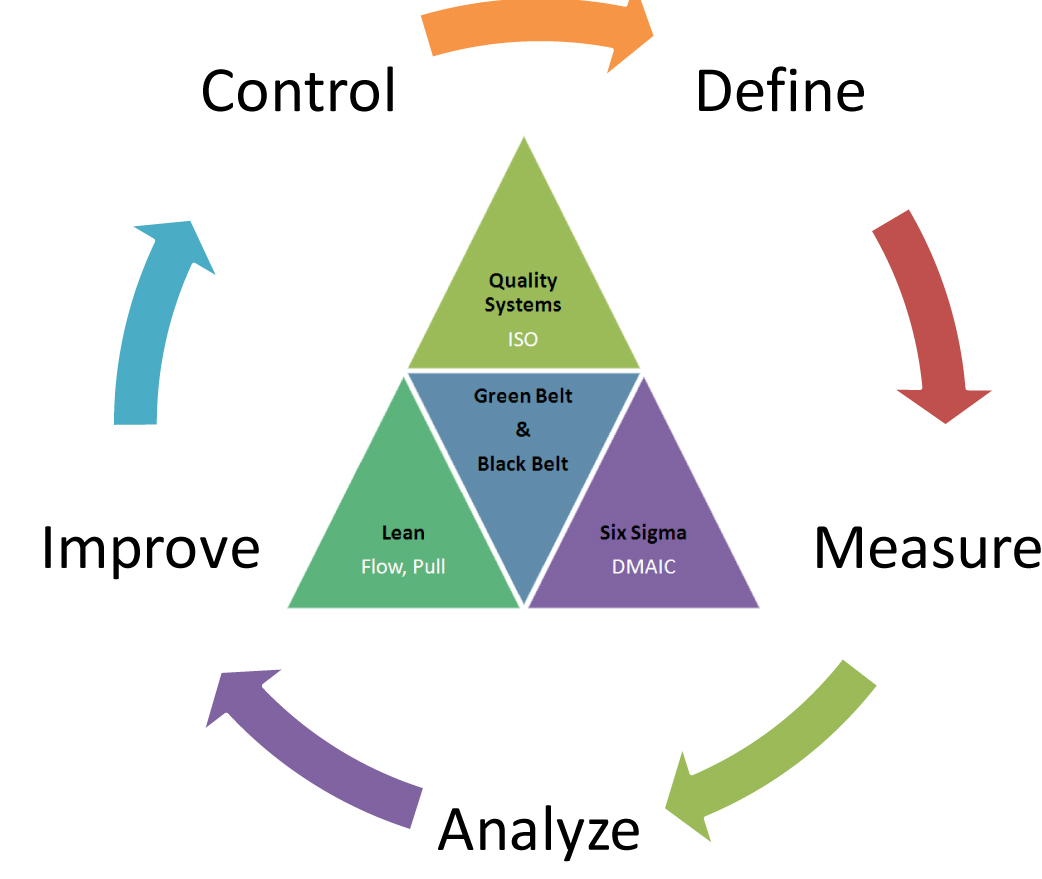

Irrespective of the industry you work in, chances are high that you heard the term ‘process improvement.' This streamlining of the business process is what Lean and Six Sigma is all about. Combined Lean and Six Sigma is a management approach that amplifies the strengths and minimizes the weaknesses of the system.

What is Quality & Continuous improvement?

Continuous quality improvement is a fundamental requirement of all businesses to grow. Quality improvement is not a one-time effort; this is an ongoing process that needs to last through the lifetime of a business. Continuous quality improvement is a system that businesses of all sizes need to employ and adapt as it focuses on quality improvement, cost reduction and enhanced efficiency.

Continuous improvement is a fundamental requirement of all businesses to grow; it is not a one-time effort; this is an ongoing process that needs to last through the lifetime of a company. Continuous improvement is a system that businesses of all sizes need to employ and adapt as it focuses on quality improvement, cost reduction, and enhanced efficiency.

The Importance of accepting Change

There is a saying, that “nothing is constant but change.” Anyone who does not adapt to changing times stops growing as Charles Darwin had famously said – It's not the fastest nor the strongest that survive, but those ablest to adjust.

In today's global market, companies need to deal with change on a day to day basis. Change or perish is the mantra of the day. Unfortunately, often businesses fail to adapt. Even massive companies like Nokia had to learn it the hard way. Nokia did not go defunct because they lacked in technology or they lost touch with their customers. They could not change in a decisive and committed way.

In the business world, changes happen without warning almost every minute of the day. Just acknowledging these changes will not offer successful business outcomes. The key is to know how to successfully navigate these changes and develop appropriate and effective processes to grow and improve; this is where concepts like Lean and Six Sigma helps. These tools prepare the leaders and the team to adapt effectively to change. Adapting to change changes along with Lean Six Sigma methodologies makes the adoption easy and smooth.

What is Lean & Six Sigma?

Lean and Six Sigma are two different approaches that have been combined to gain maximum mileage.

Lean derived from Lean manufacturing or lean production, often simply "lean," is a systematic method for waste minimization ("Muda") within a manufacturing system without sacrificing productivity. Lean also takes into account waste created through overburden ("Muri") and waste created through unevenness in workloads ("Mura").

Six Sigma is a disciplined, statistical-based, data-driven approach and continuous improvement methodology for eliminating defects in a product, process or service.

On a broader view, Lean focuses on process Acceleration while Six Sigma focuses on process Accuracy. Isn't this a beautiful combination to Accelerate Accurately? For complete success and growth, a hybrid approach of Lean & Six Sigma is essential.

Tale of Six Sigma

The roots of Six Sigma can be traced back to the early industrial era, through the eighteenth century in Europe. Carl Frederick Gauss introduced it as a conceptual normal curve metric. The evolution of Six Sigma took one step ahead with Walter Shewhart showing how three sigma deviations from the mean required a process correction. Later in the mid-1980's the Motorola Company's CEO and the engineering team developed the six sigma tools to measure the productivity process. With the implementation of Six Sigma, Motorola reached a dominant bottom line, and the company saved $16 billion as a result of the efforts. Another firm associated with the early development of Six Sigma is General Electric. In 1995, Jack Welch, the CEO of GE made Six Sigma a central part of their strategy. After that GE reported a fiscal impact of $12 Billion over the five-year period from 1995 to 2000. Since this success, Six Sigma methodologies have been adopted by numerous companies across the globe with essential success rates.

History of Lean

The origins of Lean can be traced back to Europe in 1450s, but it was but Henry Ford, who first truly integrated an entire production process in 1913 where he synthesized interchangeable parts with standard work and created flow production.

The modern concept of Lean was later developed and made accessible in the 1950s by Toyota. Taiichi Ohno of Toyota was the pioneer in introducing the idea of reducing time by reducing non-value adding waste. This Toyota Production System (TPS) has evolved over the years into a holistic system for both manufacturing and service sectors. Lean methods were devised to simplify operations, eliminate waste and carry out more value creating activities.

Benefits of Lean Six Sigma

The history of Six Sigma speaks volumes about the benefits of these tools when used by various organizations. One of the most valuable benefits of applying the Lean Six Sigma methodology for an organization is increased efficiency and elimination of waste. It helps in achieving the highest level of quality and reduces process errors to insignificant figures. With better quality and less errors, it becomes easy to have delighted customers. Delighted customers mean a better revenue stream with improved bottom line.

For individuals Six Sigma certification makes the recipient stand out from the crowd as it’s a known fact that a person with LSS certification will be committed towards improving the business process and will have leadership qualities. This very knowledge leads to better employability and improved compensation. Six Sigma certifications demand so much respect as they are not easy to attain, and executives and hiring managers in all big organizations know this.

Application of Lean Six Sigma

Applying Lean Six Sigma, is a continuous process that needs time and commitment. LSS tools lead to transformation within the company and creates more efficient processes. Lean Six Sigma techniques can be applied not only to manufacturing operations, but also for service and other business functions. Lean and Six Sigma offers inventive ways of solving day to day issues by identifying the concerns and providing diverse ways to solve them.

Lean Six Sigma techniques can be applied not only to manufacturing operations but also for IT, ITes, Healthcare, Bioscience & other services. Application of Lean Six Sigma to non-manufacturing companies is on the rise, and it will only accelerate from now on with the changing world is undergoing. Lean and Six Sigma offers inventive ways of solving day to day issues by identifying the concerns and providing diverse ways to answer them. Lean Six Sigma applied to healthcare can quickly look at enhancing the utilization of the hospital facility by 40-50% and Doctors can make use of the opportunity to examine more patients per day. Merely put Wherever there is a process Lean Six Sigma can be applied to Accelerate the process Accurately and who does not want it?

Growth & reach of Lean Sigma in today's world

In this modern-day era where technology and customer demands change with a blink of an eye, every business has to change and be ready for acceleration. Lean Six Sigma training prepares you for all these and much more. The reach of Six Sigma has increased humongous in the last decade and is all set to become more vital. Lean Six Sigma is one of the most sought-after improvement techniques today due to its flexibility and hybrid nature. The methods of LSS can be customized to accommodate the need of the company.