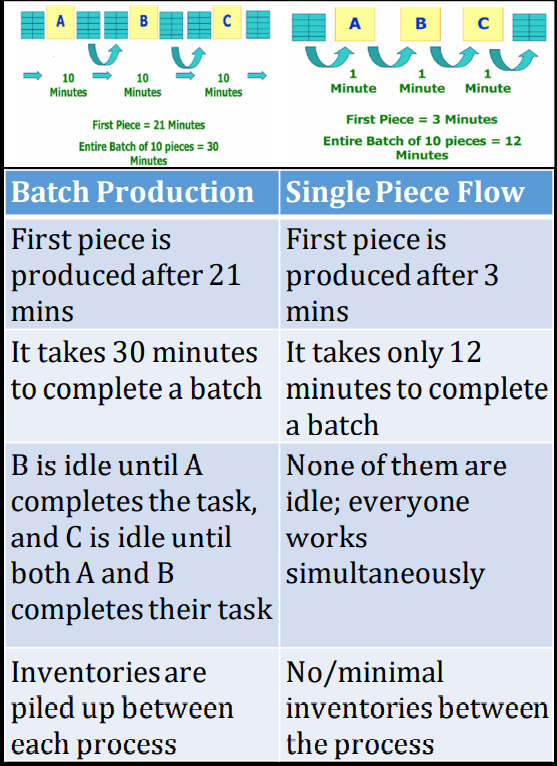

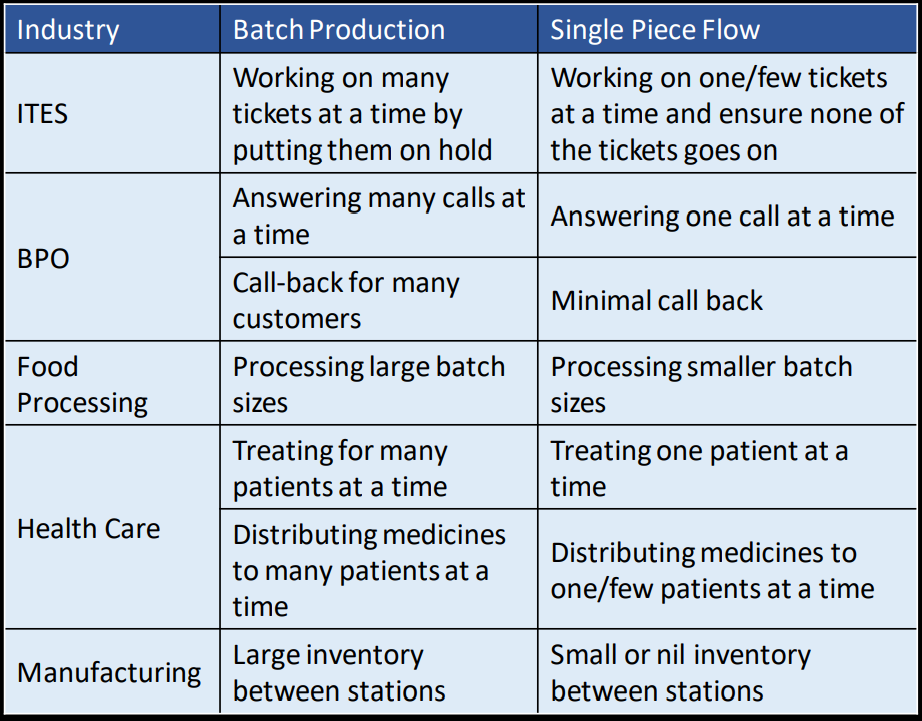

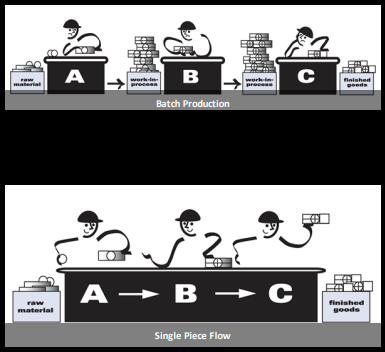

- Single Piece Flow states the concept of moving one work-piece / Service at a time between operations/processes within a work cell.

- At the opposite extreme, we might process an entire batch or lot at each operation before moving it to the next process. This idea has many benefits.

- Single piece flow works best in combination with a cellular layout.